7 Essential Things to Look for in a Palletizer

Adding an automatic palletizer – if not multiple – is an essential step for any large packaging and/or manufacturing operation. From pairs of shoes to bags of dog food, all products require properly formed palletized loads to ensure they are prepped for shipping and ensure they arrive at their final destination safe, secure, and intact. However, forming these loads during a manual palletizing process is a chore, and is typically less than ergonomic. The manual labor is strenuous and is hard on the human body and the procedure, when done by hand, is prone to mistakes. This is where palletizer systems come into play to facilitate precise, well-stacked, and reliable palletized loads ready for the shipping process time after time.

If you are considering upgrading your palletizer or adding a palletizing system to your operations, it’s important to consider all of the factors to keep in mind before putting in your order with a trusted partner. Let’s take a look at the seven essential things to look for when choosing a palletizer.

1. It Fits Your Specific Needs

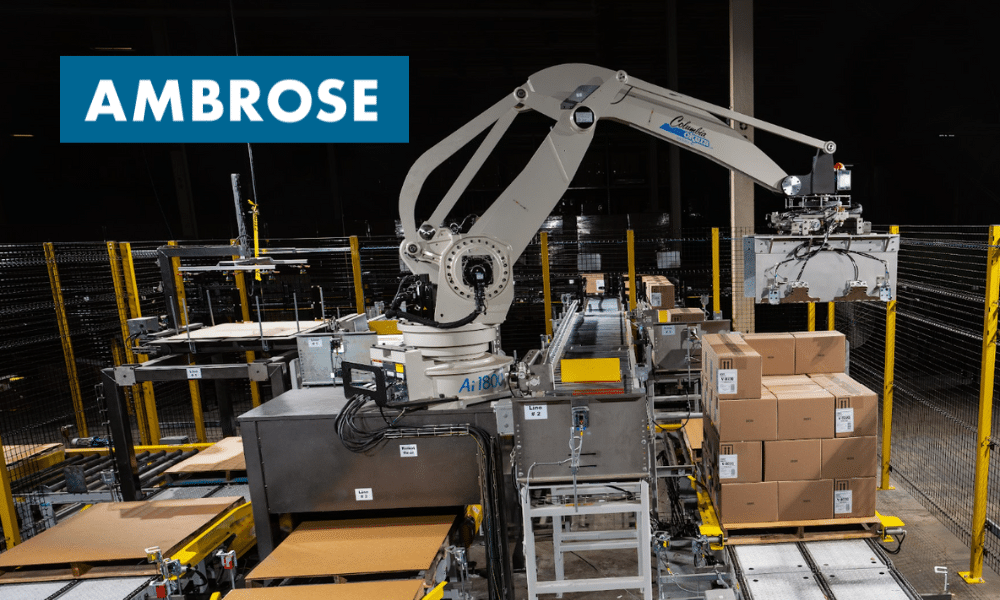

First and foremost, you’ll want to understand what you need in a palletizer in terms of design, automation and technology. While most conventional palletizers are row-forming, meaning they put together and organize tidy rows of products before stacking them on a pallet, a robotic palletizer with an end of arm tool might be a better fit for your particular production line.

Robotic palletizing systems use a robotic articulating arm to pick each individual product or multiple products at a time, and stack it to form a perfect load, simulating human stacking more closely than row forming. This process can be slower, but also more precise than row-forming palletization. If you opt for a robotic palletizer, we can help design the specific end of arm tool for your application. With hundreds of designs, and thousands of applications, the end of arm tool can vary in size, performance, and technology used.

2. Rate of Palletization

The rate of palletization refers to how quickly loads are able to be formed. Each palletizer can be measured by how quickly it can in-feed pallets based on the packaging and handling requirements of your products. You will want to gauge the rate of palletization you are looking to achieve in order to understand how important high-speed components and continuous motion are to your particular production processes. Taking into consideration pallet and load accumulation, upstream production queues, lanes of traffic feeding the palletizer, system restrictions set by product dimensions and weight, as well as total footprint of available space.

3. Adaptability for Different Products Being Palletized

Most businesses need to palletize more than one SKU or product type using the same palletizing cell. It is also possible that your packaging and palletizing needs will change over time. This means you will want to consider how well your palletizer can adapt to new requirements via programming and handling capabilities. Rates, weight, and reach (for robotic applications), must all be considered. Ambrose typically scales their system designs to accommodate for future growth opportunities, or physical capabilities of system, by factoring 25% or more of the projected current needs.

4. Palletizing Environment

Palletizing systems can be designed in many different ways, some requiring more operating space than others. How your palletizer is receives product, how loads are built and how loads are removed from the cell will all play a factor into the design. Even the conditions of the environment- wet, cold, dry, dusty, humidity, etc. are all environmental factors that must be considered. Lastly, You may also want to consider factors like power & air consumption needs, level floor, fork truck and foot traffic around the palletizer, staging areas, etc.

5. Load Removal Process

How palletized loads are removed from the palletizing cell is crucial to the end of line process. Consider an ideal workflow when comparing palletizer design options. Maybe your loads exit the palletizing cell and feed directly into an automatic stretch wrapper. Maybe your loads are picked up downstream and taken to a transfer station for storage prior to wrapping. Regardless of how loads are to be removed from the cell, take into consideration how many loads need to be accumulated downstream to ensure your fork truck drivers can get to, and from, destinations without halting the automated palletizer.

6. Human Action to Facilitate Palletizing

How automated should your palletizer be, and what human actions are necessary to facilitate effective pallet management and productive throughput? Some palletizers are almost fully automated while others are designed to accept direction and facilitate a primarily human workflow in material handling, transporting to a stretch wrapper and more. The right solution will be unique to each operation and team, and you can and should choose a palletizer that suits your operations needs.

Find the Perfect Palletizer for Your Facility with Ambrose

If your facility is in need of a high-quality palletizing solution to automate your current manufacturing or packaging production lines, Ambrose can help you design an effective palletizing solution based on your unique facility and product requirements. Contact us today to explore high-level palletization solutions, reduce downtime and maximize profits.