How Can Industrial Robotics Improve the Workflow in

Your Facility?

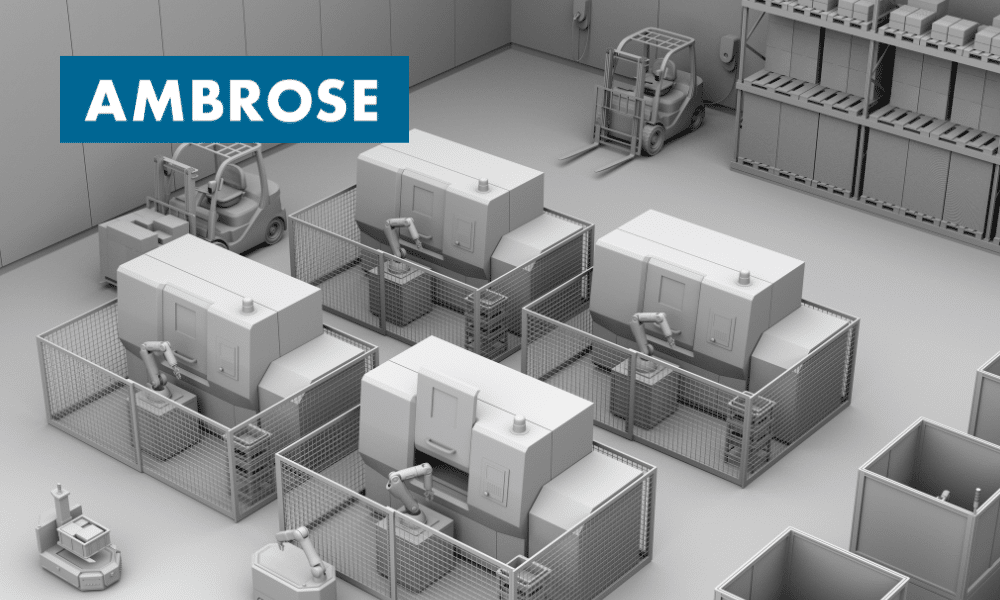

Our experts can help you design and build a robotic automation system that will take your operations and manufacturing processes to the next level. By leveraging robotic manufacturing to automate workflow, you will be able to reduce labor costs, increase productivity, eliminate costly errors and improve worker safety. As a result, you will enjoy lower production costs and measurable improvements in operating efficiencies that will translate into better profit margins and a more robust bottom line.

What Do We Mean by Industrial Robotics?

Industrial robotics is the practice of using robots to automate and streamline tasks within production processes. Robotic solutions can be implemented in almost every aspect of automation from supply chains to fulfillment centers. Robots can be used within the manufacturing industry to automate such functions as material handling, storage and retrieval, product assembly and palletizing. The use of robots is ideal for performing mundane, repetitive tasks, which frees employees to devote their time to more complex issues.

What Types of Robots Are Used in Production Lines?

There are several types of robots that are ideal for manufacturing companies and production line automation. Robots can be used in a number of operations, including high-volume assembly lines, as well as picking, sorting, storing and transportation. Here is some information about the five most commonly used robots:

Articulated robotic arms use multi-jointed mechanical limbs that are able to move, lift, turn and otherwise maneuver items. They are used in a variety of warehouse functions, including product assembly and placing assembled products into cartons. They can also be used for cutting, welding and painting. The number of joints available in articulated robotic arms varies from two to ten with six being the most common.

Collaborative robots, also referred to as cobots, operate in a semi-automatic fashion. They are designed to assist employees in such tasks as picking parts and transporting those parts to assembly stations. Employee safety can be improved by bifurcating tasks and letting robots handle activities that might pose a safety threat to humans, such as the lifting of heavy objects.

Automated storage and retrieval systems come in a variety of configurations, including cranes, shuttles and vertical lift modules. These robotic devices can quickly navigate isles, find a particular location and place an item into or retrieve an item from that location. They have the ability to reach substantial heights and are often used to replace forklifts.

Automated guided vehicles are similar to AMRs but less sophisticated. They rely on some type of a guidance system, such as a laser, inductive wire or magnetic tape. Automated guided vehicles can provide a number of automation functions, including the delivery of materials and supplies in addition to the loading and unloading of pallets.

Autonomous mobile robots can safely navigate a space independently without the need for predefined paths, tracks or operator assistance. They are equipped with cameras and rely on multiple sensors and artificial intelligence for navigation. If they encounter an obstacle, they are able to safely navigate around it or to stop and send an alert. Autonomous mobile robots can increase production speeds, enhance operational efficiencies and improve safety.

How Do Industrial Robots Work?

Robotic technology is designed and programmed to perform repetitive functions. Robots can carry out tasks in an autonomous manner without human assistance or in a collaborative manner wherein they assist humans. They can be constructed of specialty materials that can survive in almost any environment. Some industrial robots use artificial intelligence (AI) and machine learning to become more efficient in the jobs that they perform.

What Are the Benefits of Industrial Robots?

Increased safety is one of the primary benefits of using robots in your operations. Robots can be used to perform jobs that are dangerous or strenuous for human workers to complete. Increases in production can also be accomplished because of a robot’s ability to handle multiple products and multiple boxes at the same time. Robots also improve accuracy as well as quality control and are able to continuously operate around the clock with no break, no shift changes and no paid time off. Additionally, robots can be strategically placed to reduce space.

Enlist the Help of Experts Today

E-commerce sites like Amazon, Walmart and Target know the importance of leveraging robotic applications to gain efficiencies in their fulfillment centers. AMBROSE can design and implement a robotic system that will help you to gain those same efficiencies when it comes to your manufacturing automation goals. If you want to drastically improve the workflow in your facility or distribution center, reach out to our team today. One of our experts will be glad to show you how robotic integration can be applied for automation purposes and to answer any questions that you might have concerning their use.