Case Packing Machines

If you’ve gotten as far as you can having employees pack products in cases by hand, and delivery deadlines are at risk, you’ll want to explore automatic case packing equipment options.

With tailored case packing solutions, you’ll be able to greatly improve production efficiency and benefit in other ways from modern equipment that is easy to use and simple to maintain. As the case packing machine drops, picks up or pushes your products into place, you’ll get products out the door and into customers’ hands sooner, which is especially important in this just-in-time production world.

Some manufacturers have invested significantly into automated case erecting, case sealing and palletizing but continue to pack cases by hand. This is unfortunate because automated case packing systems have the ability to lower overhead costs, increase productivity and reduce on-the-job injuries.

What Is Case Packing?

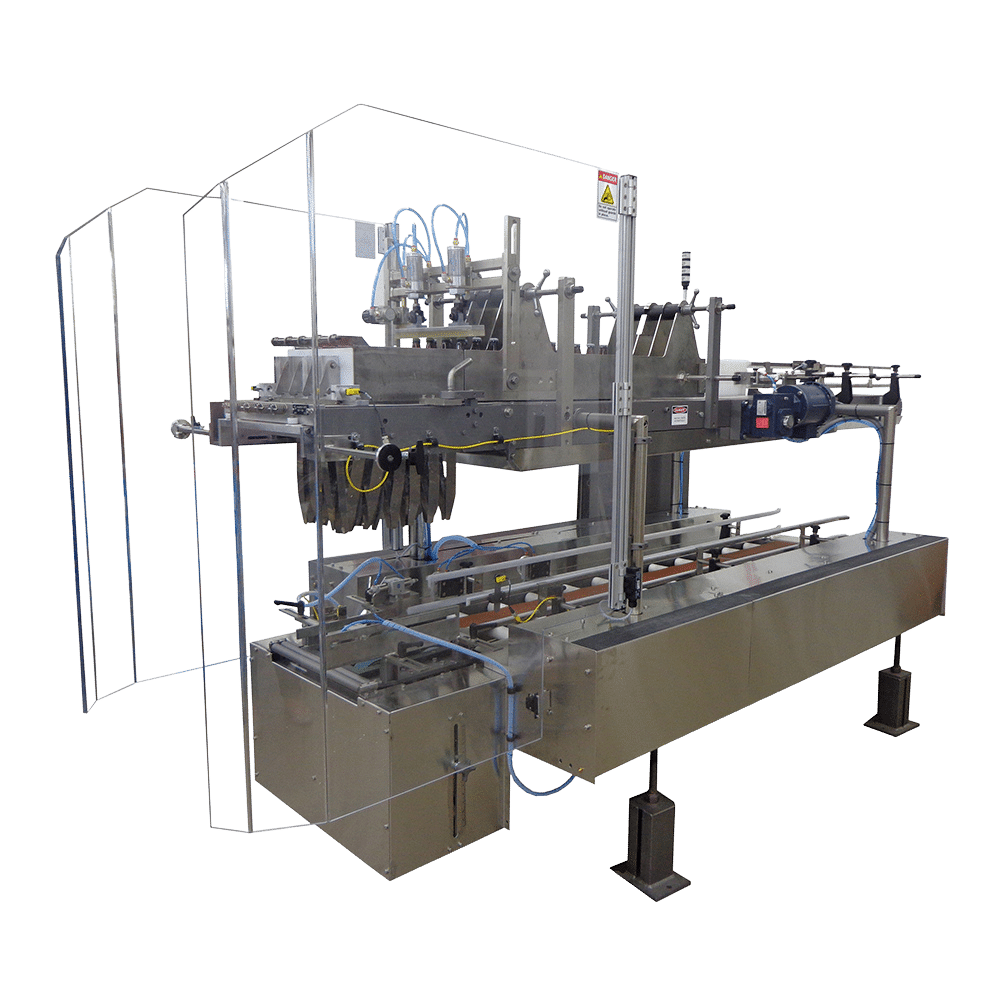

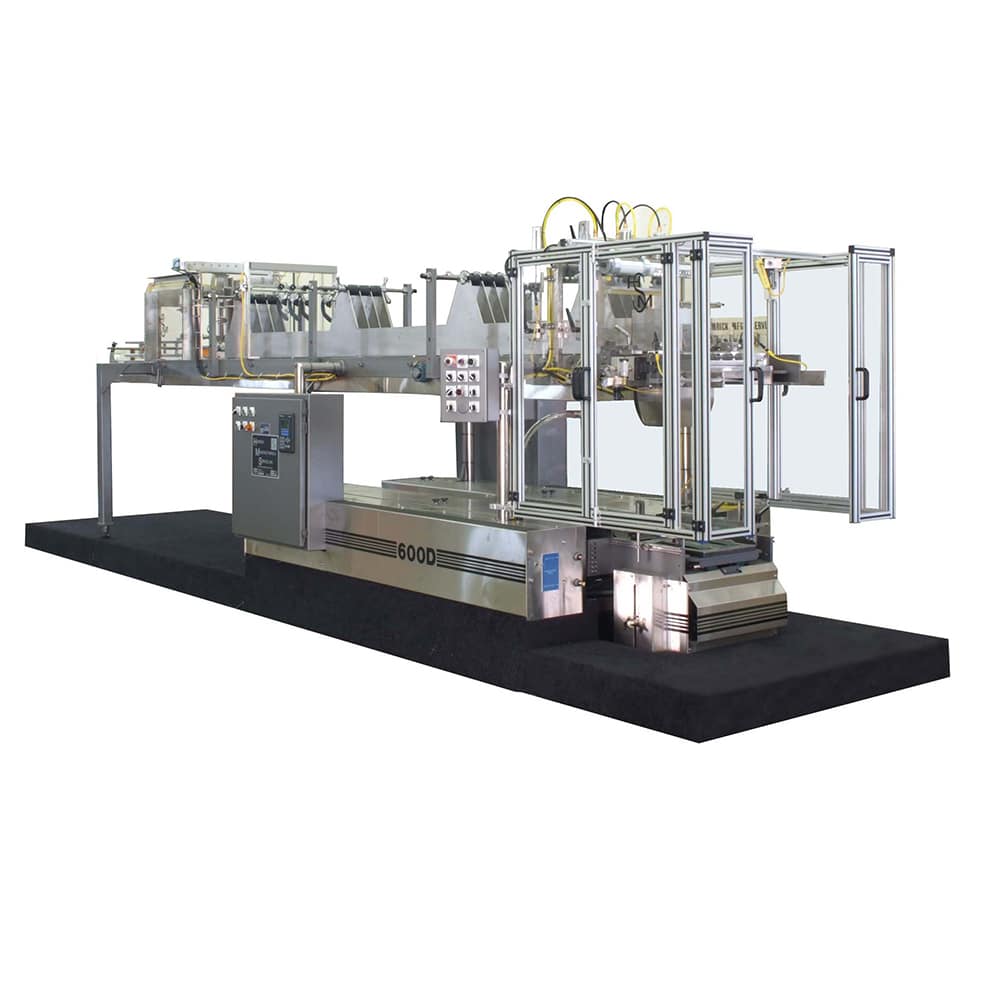

Case packing equipment loads products into a case, box or other type of container. The packing can be done by hand or automatically with equipment designed for that purpose. The term is sometimes used to describe the combined process of case erecting, packing and sealing.

Streamline Your Operation with Case Packaging Equipment

Automated case packaging equipment can streamline your entire operation and greatly improve your productivity while reducing labor costs. Case packaging machines are extremely versatile and can be customized for almost any manufacturing environment. One of the main advantages to using automated case packers is the speed at which they operate. Some case packaging systems can pack hundreds, even thousands of products per minute, and in some instances of up to 50 cases per minute or more.

Collating

Automated packing processes typically include collating. This means that products are arranged into patterns so that they can be picked up and placed or soft dropped as a group into a case. Examples might include a dozen cans arranged in a pattern of 3 x 4. Collating may also include stacking products into rows and orienting products so that they all face the same direction.

Major Methods of Automatically Packing Cases

There are three major methods of automatically packing cases: top loading, side loading and vertical placing. Here is a brief description of each:

Top Loading

Side loading has two common variations, both of which are slightly more involved than top loading. The first variation consists of leaving one side of a box unsealed so that it can be packed from that side. The side is then sealed once the box is loaded. The second variation consists of turning the box on its side so that it can be loaded through its top.

Side Loading

Side loading has two common variations, both of which are slightly more involved than top loading. The first variation consists of leaving one side of a box unsealed so that it can be packed from that side. The side is then sealed once the box is loaded. The second variation consists of turning the box on its side so that it can be loaded through its top.

Vertical Placing

Vertical placing is sometimes used for products with irregular shapes that make collating difficult. Such products are picked up and placed into the case one at a time. Vertical placing is best performed by robots. In the past, it may have been hard to justify the use of robots because of their high cost, but the price of robots has dropped significantly in the past few years, making them much more affordable.

Case Packing Solutions from Ambrose

Some manufacturers rely on manpower to pack their cases because that job can be performed by low-pay, unskilled workers. However, quality entry-level labor is getting harder to find, and the cost of one on-the-job injury can go a long way toward the purchase of an automated case packing system. If you are interested in automating your case packing, contact one of our product specialists today.

How to buy:

It’s our goal that you’re completely satisfied with the purchase of your equipment. Therefore, we will work together to determine the optimal options, supplies, installation methods, and training that best serves your application, budget and quality standards.

Speak to a Representative – Call (913) 780-5666 or email AmbroseCRT@ambroseco.com Fill out a quote request online.