Vision, Inspection, and Quality Control

Your customers depend on you to consistently deliver high quality products. Vision, inspection, and quality control equipment can be utilized to protect the quality — and integrity — of your brand.

In the manufacturing stage, this equipment can ensure proper placement of parts and collect efficiency data for analysis. In packaging, it can spot defects with x-ray scans, highlight sorting mistakes, and measure accurate product weights.

Quality control is vital in manufacturing, and QC equipment will protect your bottom line by allowing you to pinpoint defects early and prevent the kind of inaccuracies that lead to customer dissatisfaction.

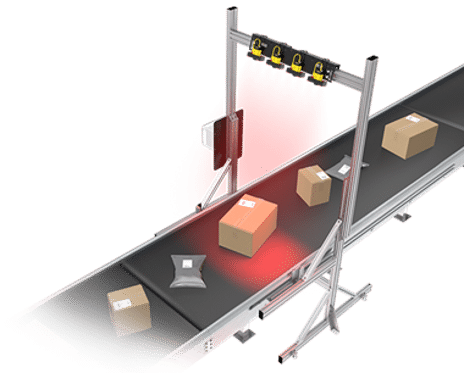

Vision inspection systems (VIS) can greatly improve quality control within a manufacturing facility. Mistakes made in the manufacturing of goods or even instances of sorting and product handling can be reduced to an absolute minimum. Employee man-hours can also be reduced because automated systems perform the majority of quality control inspections through the use of images, videos, and digital components. Vision systems provide immediate feedback and are able to detect problems that might otherwise go unnoticed and result in waste.

How Do Vision Inspection Systems Work?

VIS systems use a camera or multiple cameras to provide a constant stream of information that is fed back to a control center. Many systems also use intelligent check weighers. The automated systems inspect every phase and component of a manufacturing run to look for errors and defects. Images sent back to the system in real time are compared to standard images that have been stored in the system’s memory, and a flag or action is initiated when the images fail to match. VIS systems also generate QC inspection reports that can be used to identify the source of defective parts.

What Are the Benefits of Vision Inspection Systems?

Vision systems improve efficiency, increase productivity, and reduce expenses. They can measure parts, recognize their shape and make sure the parts are correctly positioned, all of which can be done at high speed. They also can report the position of parts to robots for improved guidance. Additionally, VIS systems can stop inefficient processes and reject unacceptable products. This results in faster QC equipment inspections, better product quality, and reduced waste. Here are some additional benefits:

- Increased uptime

- Minimized recalls

- Improved detection of underfills and overfills

- Better ability to sort products

Where Can Vision Inspection Systems Be Used?

VIS systems can be used almost anywhere that quality control equipment is needed. Typical industries that use VIS include packaging, automotive, robotics, medical imaging and electronics. Any type of manufacturing facility that presently uses human manpower for QC is a candidate for VIS due to the savings that can be realized through manpower reductions and increased efficiency.

The Ambrose Approach to Vision, Inspection and Quality Control

If you would like to learn more about how vision, inspection, and quality controls equipment can benefit your operation, give one of our product specialists a call today. We would be happy to assist you and answer any questions that you might have.

How to buy:

It’s our goal that you’re completely satisfied with the purchase of your equipment. Therefore, we will work together to determine the optimal options, supplies, installation methods, and training that best serves your application, budget and quality standards.